Capacity Chart

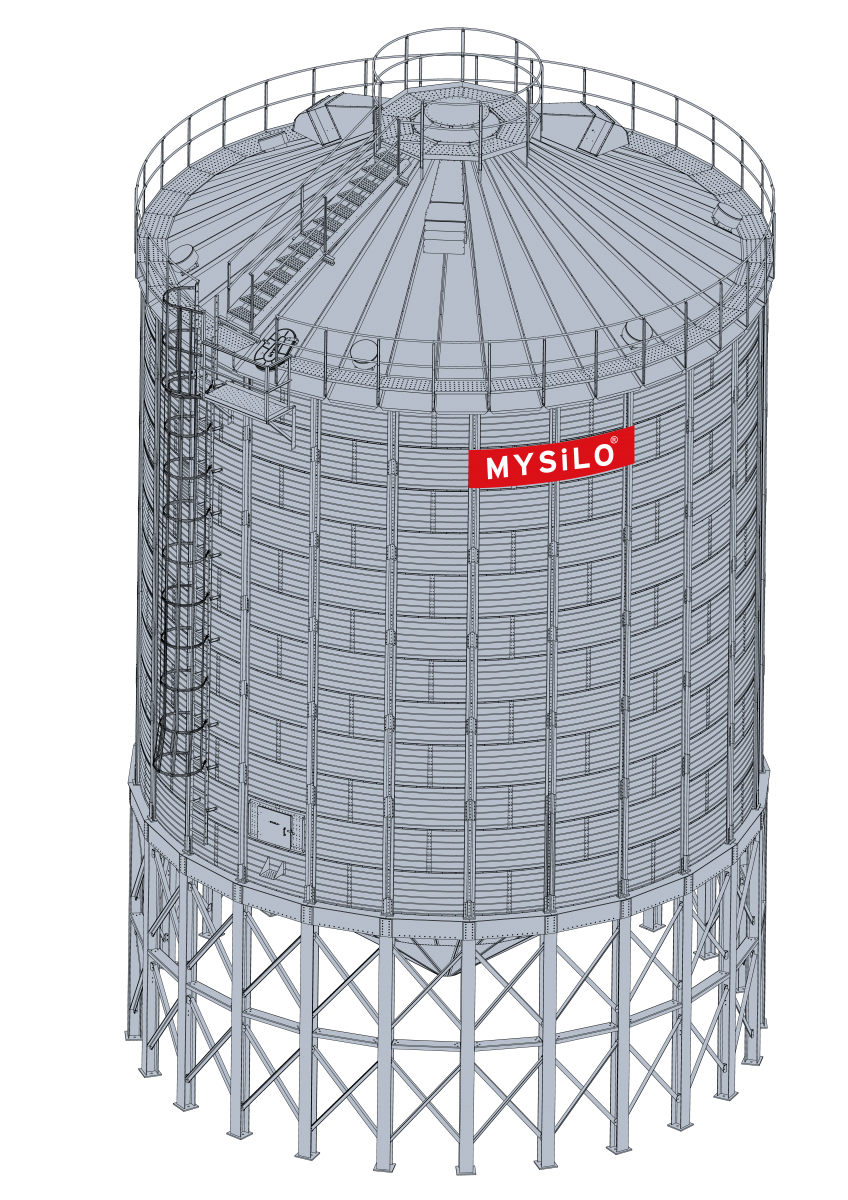

Wide range of products Mysilo manufactures different model commercial hopper base silos, diameters of which varies from 4.58 to 12,33 m and capacity up to 2.528 m³. Four different hopper angles as 37°, 40°, 45° and 60° can be manufactured according to silo diameter, grain to be stored, natural conditions of the place where silo is desired to be erected such as wind, seismic, snow loads. Hopper angle of silos vary depending on sio diameter, intended use and be stored type of product for comfort flowing. Waste of time and Money are prevented by hopper base while unloading. Hopper bottom silos can be separated into two sections. First ones which have low capacity are named Economic Hopper Bottom Silos and others which have high capacities Commercial Hopper Bottom Silos. Due to the high capacity, specially designed strong hopper structure bears the silo loads efficiently. All design details are considered for the safe grain storage.

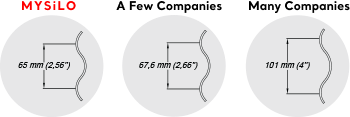

Sidewall Sheets:

Mysilo, manufacturing more durable silos thanks to the narrowest corrugated sidewall sheet of 65 mm, has a huge advantage against its competitors with this feature.

Mysilo uses 600 gr/m² galvanized sidewall sheets at total on both surfaces which makes Mysilo silos long-lasting. With this, Mysilo is making a difference to their competitors who use less coating..

Mysilo,

Mysilo,

Coating:

While competitors of Mysilo offer 600 gr. / m² galvanized coating as an option, Mysilo offers it as its Standard. Beside this, the silo’s lifetime is 0 longer** in comparison with the competitor’s standard quality galvanized coating rate 275 – 350 gr. / m²

İnsulation:

Hot and cold resistant mastic is used in the joints of sidewall sheets to provide excellent sealling in all climates

Bolt:

At all junction points of sidewall sheets and stiffeners, DACROMET 500 coated 10.9 quality bolts are used in order to ensure the maximum durability. Thanks to the high density polyethylene conical gaskets found in bolts, sealing is kept at the highest level.